BROOKS INSTRUMENT

Mass flow controller Quantim, Coriolis

Achieve superior accuracy and unmatched zero stability in ultra-low-flow gas and liquid measurement and control with the Quantim® Coriolis mass flow controllers and meters from Brooks Instrument. With the Quantim® series, Brooks has taken the lead in driving improvements in Coriolis flow technology: Our patented Quantim® Coriolis sensor design measures low flows independent of fluid type or process variables. The result: unsurpassed performance - the most accurate, stable, repeatable and reproducible mass flow measurement and control, even under changing conditions.

Features:

- True mass flow measurement

- Accurate density measurement

- 100% of fluid flows through low-mass sensor tube (no bypass)

- The Quantim® Coriolis series' proprietary optical sensing technique enables accuracy at extreme low flows

- Measures both liquids and gases over a wide flow range

- Coplanar valve delivers super-fast response times

- The Quantim® Coriolis series' offers the smallest, lowest-flow Coriolis meter and controller available on the market

- Measures and outputs two of four parameters: mass flow, volumetric flow, temperature, density

- Independent diagnostic/service port and user display

- Variety of material options, enclosure types and area classifications available

- For all gases and liquids

- Metal sealed

- Optical sensing technique enables accuracy at extreme low flows

Selected variant

Specifications

| Approvals | EMC Directive 89/336EEC per EN 50081-2 and EN 61326-1, II 2 G EEx d IIB T6 and II 2 D T 85OC per EN 50014, EN 50018 and EN 50281-1-1, II 3 G EEx nA II T4 and II 3D T 135 C per EN 60079-15: 2003 and EN 50281-1-1: 1998 + A1, KEMA 04ATEX1241 X II3G EEx nA II T4 per EN 60070-15: 2003, Pressure Equipment Directive |

|---|---|

| Control range | 1-100 % |

| Density Range Max | 2 g/cm³ |

| Density Range Min | 0,2 g/cm³ |

| IP Class | IP40, IP66, IP66XP |

| Lowest flow | 10-27000 gr/h |

| Material of seals | EPDM, Buna, Kalrez, Neoprene, Viton |

| Materials Wetted Parts | Hastelloy, Stainless steel 17-7 PH, Stainless steel 316 |

| Pressure Range Max | 300 bar |

|---|---|

| Response time | <0.5s - <2 s |

| Temperature range from | 5 °C |

| Temperature range of media to | 65 °C |

| Temperature range to | 65 °C |

| Valve type | NC |

Product description

Achieve superior accuracy and unmatched zero stability in ultra-low-flow gas and liquid measurement and control with the Quantim® Coriolis mass flow controllers and meters from Brooks Instrument. With the Quantim® series, Brooks has taken the lead in driving improvements in Coriolis flow technology: Our patented Quantim® Coriolis sensor design measures low flows independent of fluid type or process variables. The result: unsurpassed performance - the most accurate, stable, repeatable and reproducible mass flow measurement and control, even under changing conditions.

Features:

- True mass flow measurement

- Accurate density measurement

- 100% of fluid flows through low-mass sensor tube (no bypass)

- The Quantim® Coriolis series' proprietary optical sensing technique enables accuracy at extreme low flows

- Measures both liquids and gases over a wide flow range

- Coplanar valve delivers super-fast response times

- The Quantim® Coriolis series' offers the smallest, lowest-flow Coriolis meter and controller available on the market

- Measures and outputs two of four parameters: mass flow, volumetric flow, temperature, density

- Independent diagnostic/service port and user display

- Variety of material options, enclosure types and area classifications available

Related

Strategic agreement between OEM Automatic and KUKA Nordic

The strategic partnership between OEM Automatic and KUKA Nordic is driving sales momentum. Read more!

OEM Automatic now sells world leading cobots

Thanks to the new cooperation between OEM and KUKA Nordic, we are now able to offer our customers state-of-the-art cobots! Read more about the cooperation!

Push-In sockets that save both time and space

ComatReleco has launched a new series of push-in sockets specifically designed for time and space savings.

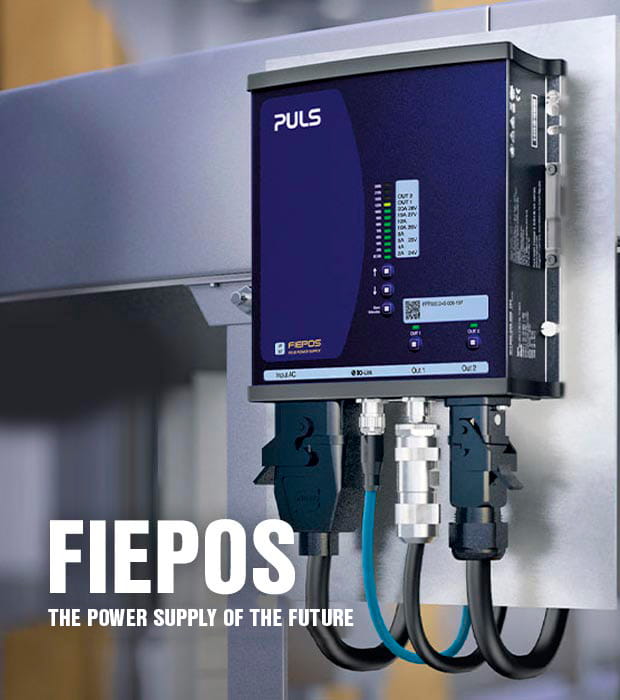

Fiepos — The power supply of the future

The need for flexible, modular systems shapes machine and system engineering. Decentralization of the system components has proven to be an important factor for success.

New “all-round” Syr-Line time relays by Crouzet

Crouzet has honoured the strong Syrelec time relay traditions established in the 1980s, first by Cronos and Cronos 2 series. Now, Crouzet presents the compact and extremely versatile Syr-Line series.

2D laser scanners

The Hokuyo 2D laser scanners measure the distance between the scanner and the environment. The scanner can detect size, location and target movement direction based on target scanning data.